mtiracing

A&A 2014-2019 Corvette Supercharger Kit

A&A 2014-2019 Corvette Supercharger Kit

Couldn't load pickup availability

A&A 2014 Corvette Supercharger Kit

A&A Corvette- Home of the world’s first Centrifugally Supercharged C7 Corvette!

A&A Corvette produced the first C7 Corvette supercharger system in October of 2013. After much testing and a few “tweaks” here and there, production systems became available in January of 2014. Aesthetically as well as mechanically, we believe this to be the finest system available for the new C7 Stingray.

Take a close look and we’re sure you’ll agree!

Advantages of the A&A Supercharger system:

Proprietary supercharger units built specifically for A&A Corvette by Vortech Engineering are used exclusively. We have found Vortech to build the most efficient units available and to also offer us the best available customer service and support. Self- contained V3 Si head units are standard. The Si units are the most efficient model available in the 500 to 700 horsepower range. All our units are available in a highly polished or satin black finish.

We have larger units available, capable of well over 1000 horsepower for properly built engines.

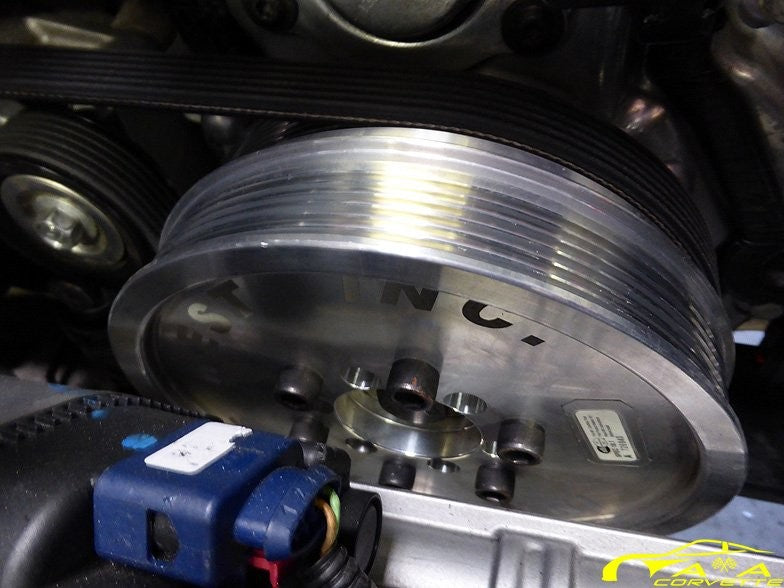

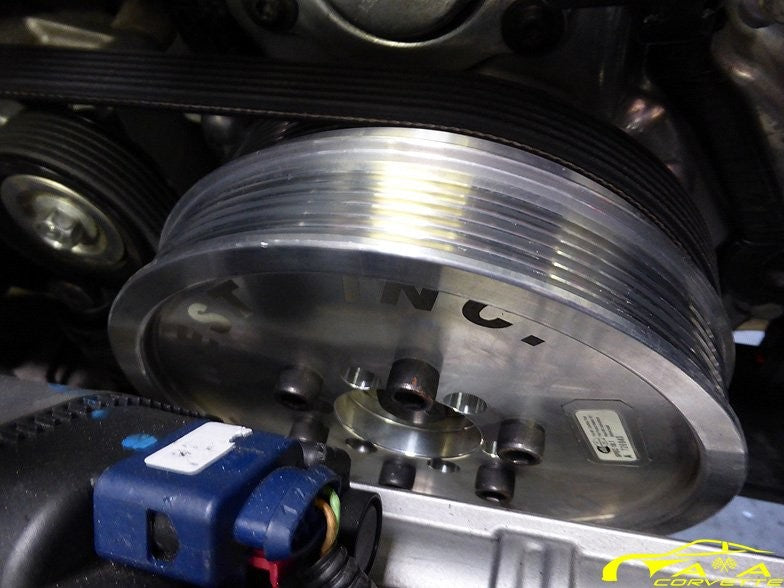

A&A is the only manufacturer to include a fully machined SFI approved balancer with interchangeable lower pulleys as standard equipment. Others just use a simple pulley that bolts to the stock cast iron balancer. Which would you trust?This balancer design allows us to use a dedicated 8 rib belt that does not interfere with the water pump or alternator belt.

A&A continues as the leader in intercooler design with our new C7 Ram Air Intercooler. GM did a great job sealing in the radiator cavity from the grill opening to the radiator. This whole cavity is a high pressure area when the vehicle is at speed. After carefully looking at all placement and airflow direction options, we came up with our present design. The intercooler lays flat and is hidden behind the bumper cover. We weld an aluminum scoop to the intercooler which protrudes into the incoming air stream and directs it through the intercooler and out the bottom. Any air that is grabbed by the scoop is literally rammed through the intercooler core. Simple physics won’t allow it to go anywhere else. Hence the name “Ram Air Intercooler”.

Others went with the flat placement but forgot all about directing airflow through the cooler. Laying the intercooler flat and putting a plastic air dam behind it just isn’t going to work efficiently. Not only are they asking the air to abruptly make a right angle turn, they’re also trying to get the air to flow from a low pressure area (under the car) into a high pressure area (inside the radiator cavity.) A&A wins this one hands down.

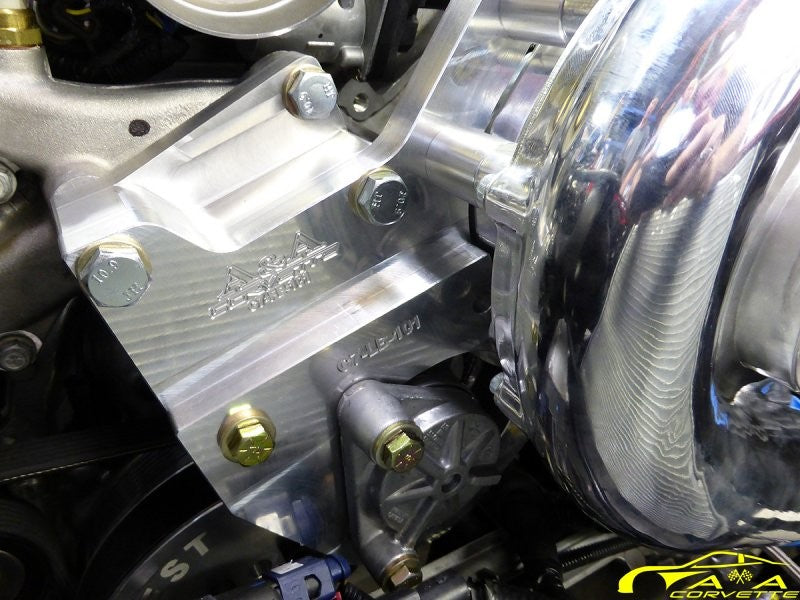

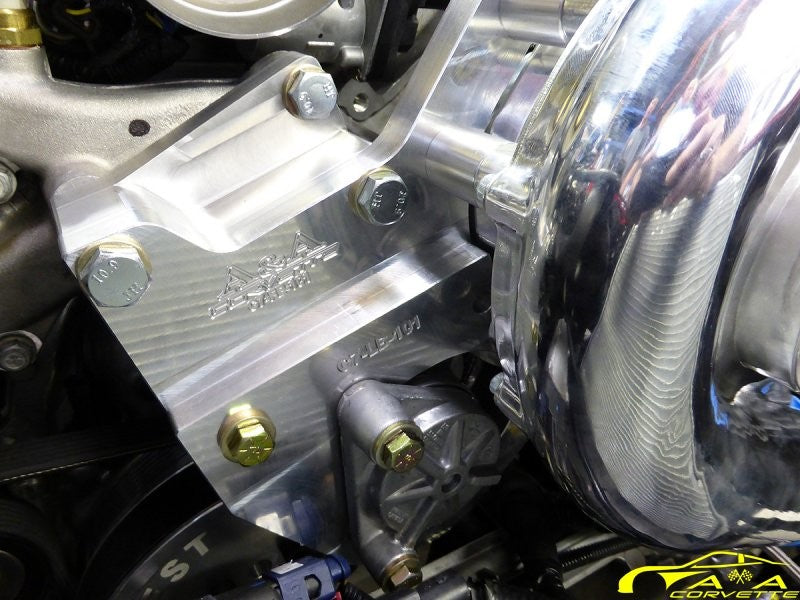

Our bracket design once again stands out from the crowd. Amazingly stiff while remaining simple, it really is a work of art. We have solid billet mounts that attach the main bracket to the block and the cylinder head. Our cylinder head mount has FOUR mounting points. Others use a simple spacer with one long bolt going through the middle. This can rotate under extreme forces. Ours simply cannot move in any direction. Our bracket uses steel idler and tensioner pulleys with dual bearings and the proper stanchions to support the bearings.

Share